The aim of VSM action at SYNGENTA was to capture its processes with VSM approach, in order to:

• Create a single picture of the value flow and generate potential improvement points (where there is “waste”, value added work versus non-value)

• Communicate the lean philosophy in the staff and its participation in the recording and evaluation of the company’s activities

The action was implemented in two phases:

Operation analysis and data collection

In this phase, the activities of each department were recorded at a high level to gather the data needed for the overall recording of the VSM.

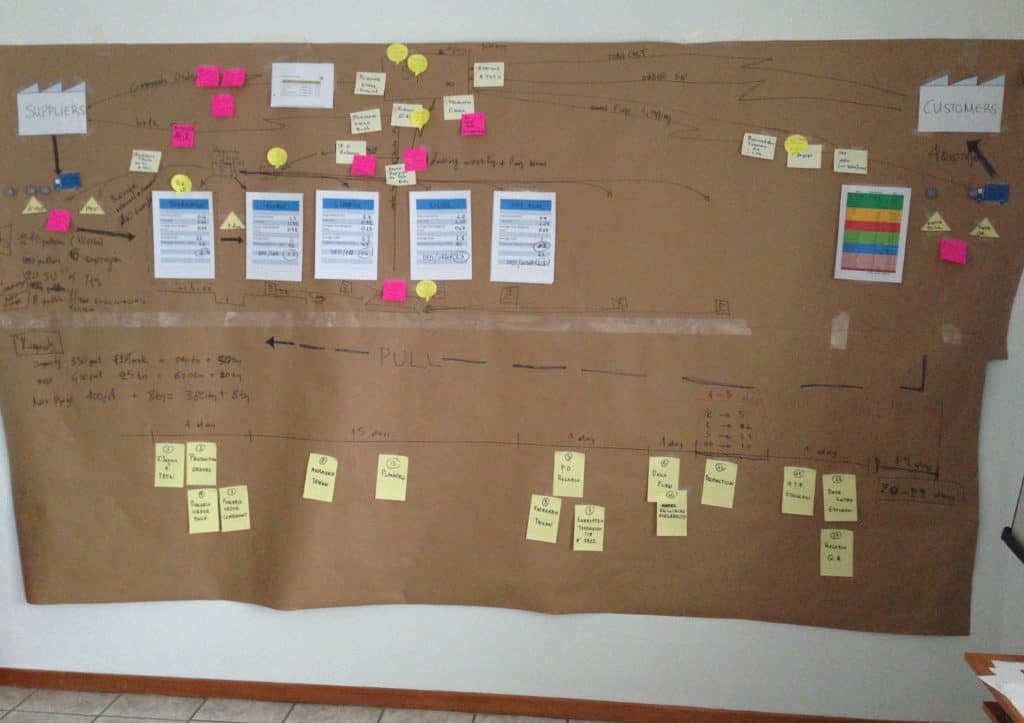

Imprint of VSM current and future state

This phase took place in the form of a one-week workshop, where VSM current state was recorded and ideas for improvement were collected, discussed and evaluated, and finally captured in the form of VSM future state. The workshop ended with the plan of medium- and long-term actions.