Measure production and increase productivity

LEAN FACTORY is an innovative production management software that supports the application of Lean methodology and helps increase productivity.

It is addressed to companies of any size, with production through distinct phases of processing and/or assembly. It provides real-time production data and prepares the company for the new Industry 4.0 environment.

Improving performance through better production and time management

Identification of production phases with excessive workloads (bottlenecks) to ensure the balance of resources

Capacity plan to ensure compliance with delivery times

Error elimination through online production management

Paper reduction and distribution of work in production with interactive screens

Remote production control with real-time display via internet

Items management

Items management based on production characteristics, instead of their commercial characteristics. Production flows approach, without production and consumption of semi-finished products in each phase, as required by ERP systems.

Import data from external systems

Many ways of data import from external systems directly or via excel. Ability to connect to any ERP.

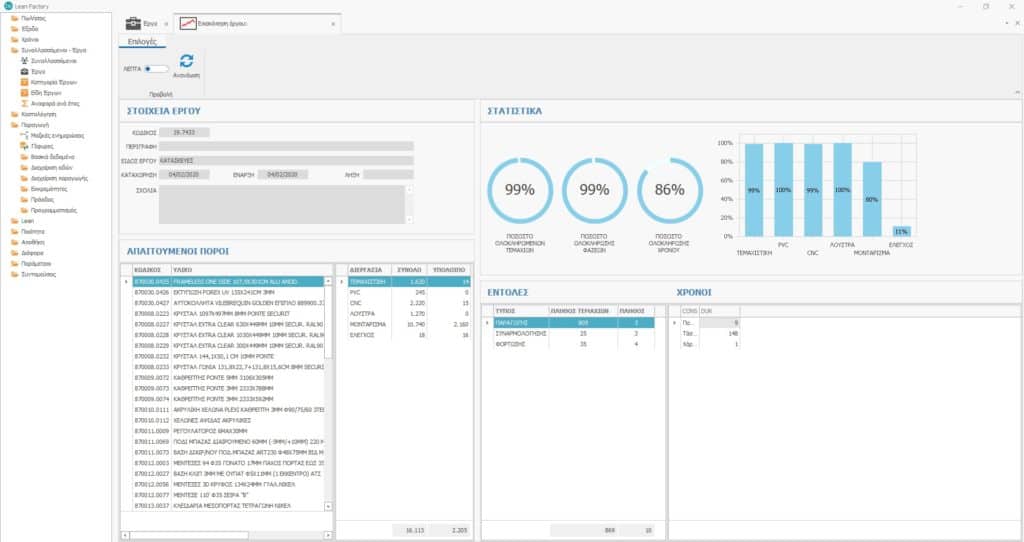

Capacity calculation

Calculation of necessary resources for the implementation of customer sales orders or production orders in the predetermined delivery times. Monitoring the completion of production and delivery objectives.

Production, Assembly, Shipment

Production management with distinct production, assembly and shipment orders. The production work is automatically distributed in the processing phases based on the flow of products and is accompanied by a list of necessary materials. During shipment, the packages are determined, and corresponding labels are printed.

Production data insertion

Insert of production data (quantities, delays, quality measurements) by the operators, in specially designed screens, where the operator sees his work list and

selects the completed ones.

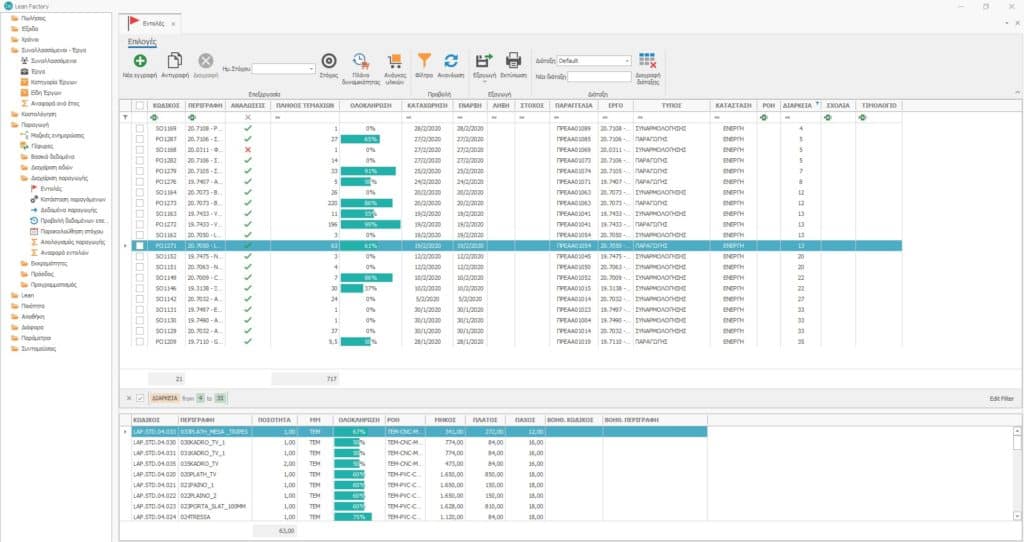

Real-time production visualization

List of production orders, assembly and shipment with illustration of the progress of each order (implementation rate) and overview with analysis of the completed processing phases.

Stock Management, Traceability

Stock management at the level of raw materials and finished products. Traceability

through lot management and serial numbers in all directions (forward, backward).

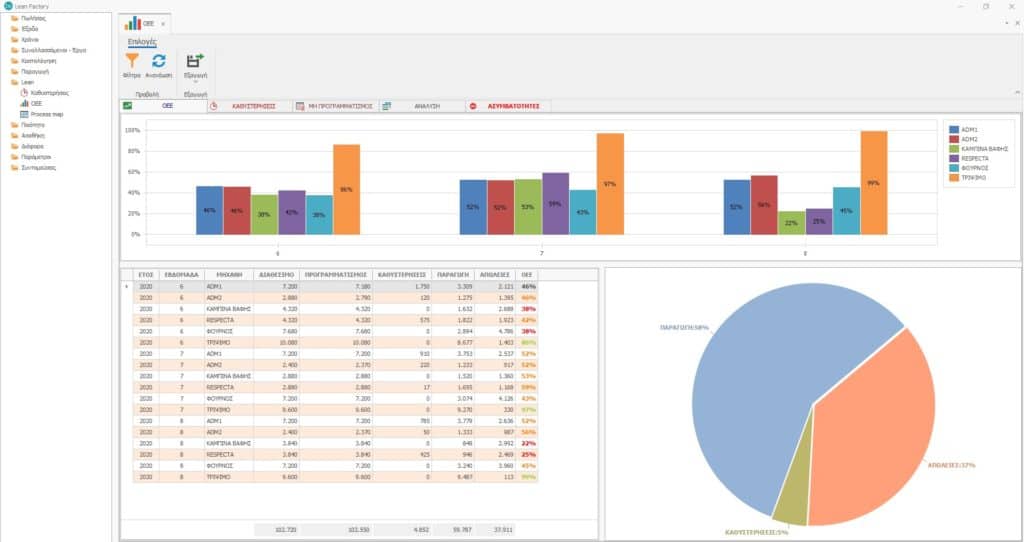

Productivity Indicator (OEE)

Overall Equipment Effectiveness, which is the central indicator of productivity

according to lean methodology. It collects the losses separated in three main

categories: availability, performance, quality.

Dashboard

Visualization of gathered progress data, resource usage and material consumption.

Statistics for integrated administrative information and decision-making support.

Cloud Based

- Increased Security

- Remote Mobility

- Automatic SQL Update

- Automatic backup

- Extensibility

- Reduced maintenance costs

Services

- Need analysis

- Configuration

- Education

- Support (on-site, remote)

- Preventive maintenance

New versions

- Continuous integration of improvement proposals

- Expansion to new functions

- Simultaneous development of business and software